Quality

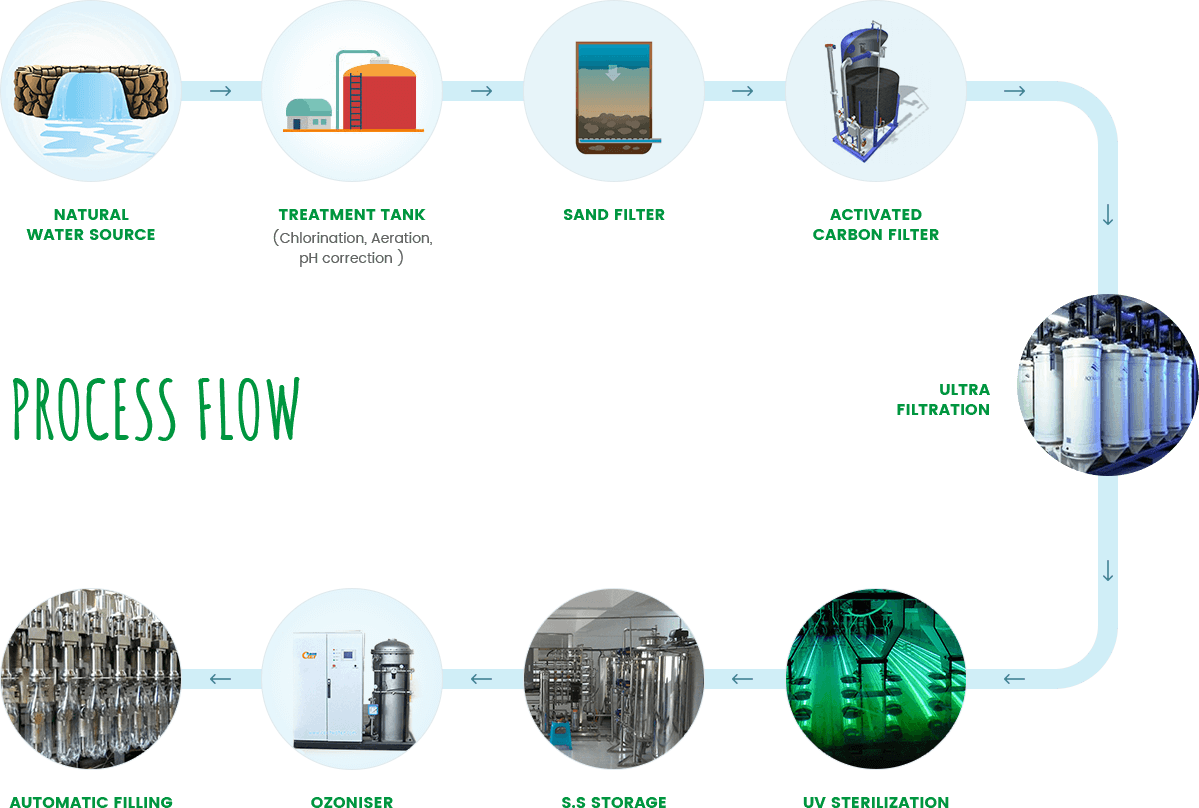

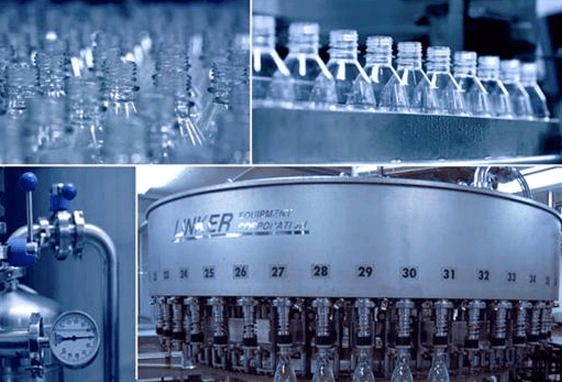

One of the main advantages of “Green Valley” products is the high quality of our source water. The subterranean water source is a highly secured well protected from all possible contaminations. The raw water conforms to all chemical and organoleptic specifications of BIS. A near zero level of microbiological contamination is maintained by chlorination, activated carbon filter, microfiltration, ultra filtration, UV sterilization and ozone treatment.

We endeavour to ensure that the ‘Natural Sweetness’ of our well water is not lost during the treatment process, which will be vouchsafed by the more discerning customers.